hrc hardness tester|rockwell model 1900 hardness tester : broker There are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more A loira mais gostosa da América latina Veja mais em https://ouo.io/HY7HJ6 2 min. 2 min Arc-Woman - 360p. Hotest Anal Fuck - Sexy Blonde Odama 25 sec. 25 sec Johanson1978 - 360p. Hot Blonde Gives Older Guy Awesome Fuck 5 min. 5 min Frankiebank - 360p. Hottest blonde teen in porn Lilly Lebeau 2 5 min.

{plog:ftitle_list}

webElephant Bet is operated by MOTA, TAVARES & BARROS SA - NIF 5417259144 - Licence N° B20081200360166654683/ISJ/MF/20

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use . See more

The differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See moreThe Rockwell hardness test can be conducted on several various hardness testers. All testers, however, fall under one of three categories. Bench model hardness testers can be found . See moreThere are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more

• International (ISO)• US standard (ASTM International) See more• Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more• Video on the Rockwell hardness test• Hardness Conversion Chart• Rockwell to brinell conversion chart• Hardness Conversion Table See moreThe most common Rockwell method in practice is HRC. In principle, ball indenters are used for the hardness tests on softer materials and diamond indenters for testing harder materials. The diamond would destroy softer .

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial .1/16" Carbide Ball Indenter Hardness test Block 60 HRC Hardness test Block 60 HRC AC Adapter Hardness test Block 30 HRC Hardness test Block 30 HRC Users Manual Hardness test Block 90 HRBW Hardness test Block 90 HRBW Vinyl Cover Hardness test Block 65 HR30N Accessory Box Hardness test Block 70 HR30TW Level Scale HardnessRockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, .

Any value ranging in the mid-50s and above on the HRC hardness scale is considered hard. However, a high Rockwell hardness HRC number doesn’t necessarily mean it’s the best metal for a particular application. Superficial Scales. The Rockwell Hardness Test . In the Rockwell hardness test, an indenter is pressed into the material. The indentation depth serves as a measure of the hardness! In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 .Analog rockwell hardness tester, hrc, model name/number: 250. Digital shore hardness tester, model name/number: mextech, 0. White lcd load cell based touch screen rockwell cum superfic. Digital asi rock-150t automatic rockwe:ll hardness tester; Portable metal hardness tester pce-900;In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. . Example 1: A regular Rockwell hardness method (HRC) 45 HRC. The number 45 represents the hardness value of the material. HR is the abbreviation for Rockwell hardness.

Dalam pengukuran kekerasan material dengan Digital Rockwell Hardness Tester, pemilihan skala antara HRC dan HRB penting untuk aplikasi yang berbeda. Skala HRC cocok untuk logam keras dan tahan aus, sementara HRB lebih sesuai untuk material lunak dengan kekuatan moderat. Selebihnya, teknologi digital juga memiliki fungsi dalam meningkatkan .

Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. Capabilities. Processes. Heat Treating. Annealing; . HRC – Known as “Rockwell C,” a 150 kgf load is .Clark Portable Rockwell Type Hardness Tester Model CPT Test Kit Includes: Unit, HRB scale hardness standard, 1/16” ball indenter, flat anvil, V anvil, Convex anvil, Carrying Case, Conversion Chart, Operation and Maintenance Manual. . Clark Hardness Standard w/ NIST Traceability (HRC) HT-ST-A-10P Create New Saved List; 0.00 Quote Cart .Portable Leeb Hardness Tester Kit with Test Block,Hardness Testing Equipment,Rockwell Metal Hardness Meter Durometer for Steel,Aluminum Alloy,Copper,7-in-1 HL, HV, HB, HRC, HRB, HRA, HS 7 8.98 $ 198 . 98

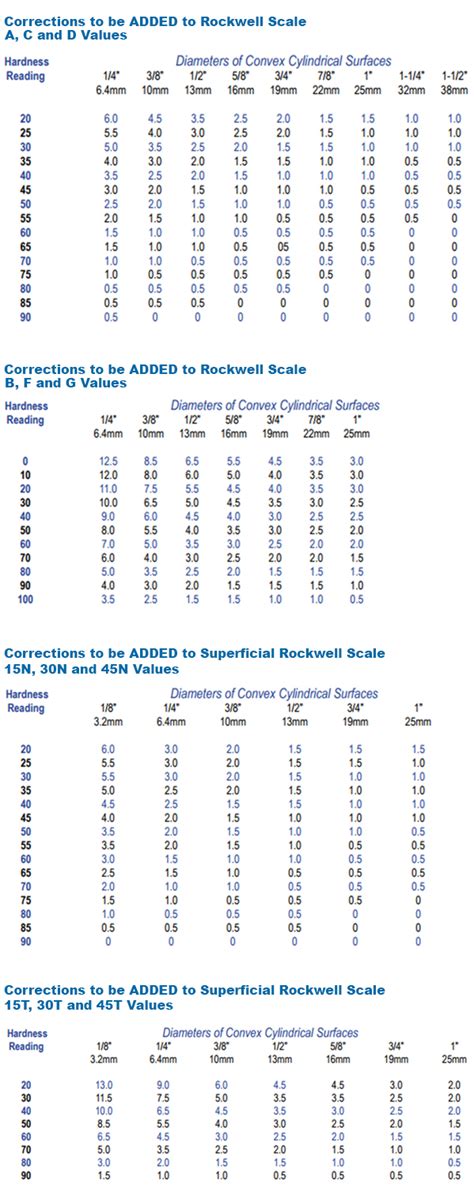

roundness correction factors chart

The hardness tester products you will find at PCE Instruments (PCE) are used for determining surface hardness. Each hardness tester uses a standard method of measurement. The measuring principles of most hardness tester devices are based on either the penetration of a diamond. . Testing of HRC, HRB, HV, HB, HSD .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .

HV, HB, HRC Hardness Comparison Chart. Hardness testing is the simplest and most straightforward method among mechanical property tests. In order to replace certain mechanical property tests with hardness tests, a relatively accurate conversion relationship between hardness and strength is needed in production.. Experience has shown that there is .

Wilson Rockwell hardness test blocks set the standard for the industry and are made from the highest quality material to insure the most uniform and repeatable Rockwell test blocks available. . HRC Scale; Certified with Diamond Brale .The e-handy is a unique portable hardness tester that determines hardness by measuring electrical resistance and can measure extremely small areas that are physically inaccessible to other hardness testers, all with maximum precision .This rebound hardness tester features a universal D impact device and is capable of displaying measurements in 7 hardness scales. The R9030 features a rechargeable battery, internal memory to store up to 350 measurements and .

Hardness testing is widely used in a multitude of industries and plays particular significance in structural, aerospace, automotive, quality control, failure analysis, and many other forms of . by the Rockwell HRC and HRB scales for testing most steels, brass, and other metals. With the increasing use of materials other than common steel Portable hardness tester is able to 360 degrees measurement and measure metal weight greater than 2.2lb. The screen of metal hardness tester has a backlight function which can be clearly displayed in dark conditions. . SUNNYSONG Portable Brinell Hardness Tester KH180,can be Freely Converted to All Hardness Systems (HL, HB, HRB, HRC, HRA, .The Wilson® hardness brand of hardness testers was originally known as the Wilson Mechanical Instrument Company. Here Stanley Rockwell and founder Charles H. Wilson introduced the Rockwell hardness tester, an industry standard.

REED Instruments Hardness Testers (also known as ''Durometers'') verify the hardness of materials. Whether you're looking to measure Shore A, Rockwell (HRC, HRB, HRA), Brinell (HB), Leeb (HL), Vickers (HV), or Shore (HS), REED Instruments has you covered. All REED hardness testers are covered by a standard 1-year manufacturer's warranty.A dependable analog or digital hardness tester from Grainger can help you accurately determine the hardness value of various materials. Shop here for Rockwell hardness testers that can measure materials from soft-bearing metals to carbides. Brinell testers help you accurately test steel parts such as castings and forgings.Being able to test the hardness of parts quickly and cheaply is invaluable for creating a performance profile of a part. So far it seems on point when used correctly. The parts I know the heat treat of came in right where they should. If you need high precision then you need the expensive tools. But for 99% of us in the real world this is .hardness tester test is widely used in the production, become the inspection product quality, the main detection methods to determine the reasonable processing technology. . (13) to the location of the 1471 n, will be 35‐55 HRC standard hardness block on the worktable, rotate handwheel (27) make the hardness of the jacking axis, combined .

Newage Hardness Testers Selection Guide Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor .

rockwell superficial hardness tester

1999 triumph sprint st compression test site www.triumphrat.net

Rockwell hardness (HRC) = BHN/10-3 hardness measurement range: HS<100HB<500HRC<70HV<1300(80~88)HRA, (85~95) HRB, (20~70 )HRC In Rockwell hardness, A, B, C in HRA, HRB, HRC, etc. are three different standards, called scale A, scale B, and scale C. Rockwell hardness test is one of several common indentation hardness tests .

Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness Testing. Hardness testing is important for a number of different reasons. The hardness of a material can be a critical parameter in its .

1999 twin cam compression test

rockwell model 1900 hardness tester

WEBr/babycaroline_69: Caroline Lopes / 21 years old

hrc hardness tester|rockwell model 1900 hardness tester